Introduction of silicon manganese Iron slag

silicon manganese iron slag is the by-product during manufacturing the silicon manganese alloy,which is applied in the manufacture of virtually all types of steel and iron castings due to its desulfurizing and deoxidizing properties .

There are two types of slag formed in the production of silicomanganese alloy: the rich slag, which is acidic, presents high Mn contents (above 40 %), being recyclable and reused as an input in FeSiMn production (besides having very low phosphorus content, which is an advantage for the FeSiMn production), and poor basic slag, which has low manganese content (MnO < 20 %) and about 30 % of Si is produced by upgrading the standard alloy through addition of silicon waste from the iron silicon industry, which at the end of the ferroalloy production process, is discarded.

What we process in metal recovery plant is also the poor basic slag.There are two types of silicomanganese slag: water-granulated slag and dry bulky slag, so we have two treatment process of silicomanganese slag to introduce.

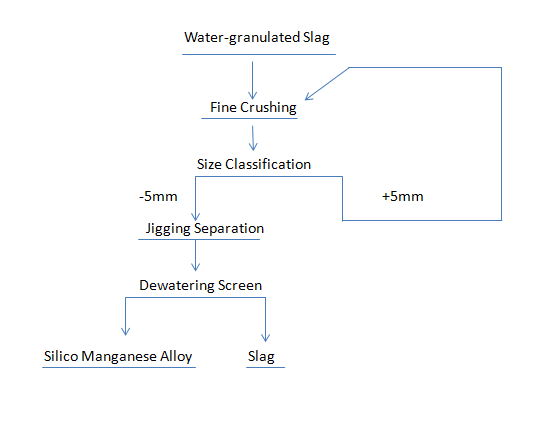

1. water-granulated silicon-manganese iron slag

The water-granulated slag is loose and granular. The alloy in water-granulated slag is with high liberation degree, simple crushing circuit is used. The crushed slag is fed to gravity separator to recover the alloy.

water-granulated silicon-manganese iron slag washing process flowsheet

video of water-granulated silicon-manganese iron slag washing plant

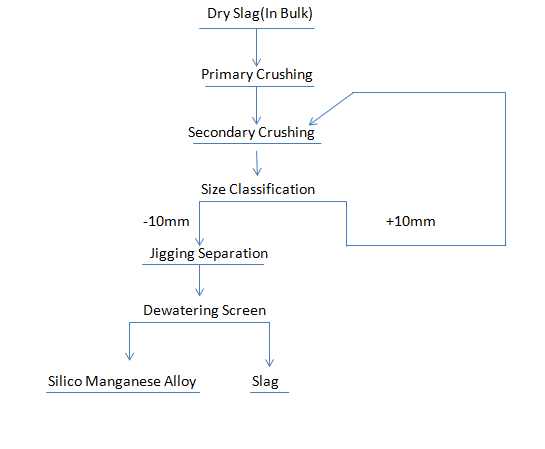

2. Dry lumpy silicon manganese Iron slag

The dry slag is lumpy and large in size, the alloy is embedded in the slag. Two-stage crushing is necessary to liberate the alloy from slag. After crushing, the jig machine is used to recover the alloy.

Dry silicon manganese Iron slag washing process flowchart

Video of Dry silicon manganese iron slag washing plant

Working principle silicon manganese iron slag process

The silicomanganese alloy which features coarse size distribution and have big density, there is big difference in density between slag and silicon manganese alloy, so alloy can be recovered by using the gravity separation .

Silicon manganese slag washing plant

In the silicon manganese iron slag washing plant, the main separation machine involved is the siliconmanganese slag jig machine.Jig machine is a compact and efficient gravity separation device which is widely untilized throughout the world.The jig machine has many advantages such as high recovery, high unit throughput, low water consumption, simple operation, low installation cost, low operating costs and high security.

Professional supplier of silicon manganese iron slag washing plant

Forui Machinery Factory has 20 years experience in slag recycling. Hundreds of commercial silicomanganese slag washing plants have been built and are now operating all over the world. We have long term contracts in place with smelters in China, India, Iran, Sultanate of Oman, Bangladesh , South Africa, Zimbabwe, etc.

Our silicon manganese slag washing plant

In China

In Iran

In India

Related Articles of silicon manganese process

1. China Minmetals Purchased Silicomanganese slag Washing Equipments from Forui

If any enquiry of ferrochrome slag jigging process, welcome to contact us: Send Enquiry

Email: This email address is being protected from spambots. You need JavaScript enabled to view it. whatsapp/wechat: +86 18037167566