Brief Introduction of Double Roll Crusher

Double Roll Crusher (or Roller Crusher) is used for middle crushing and fine crushing of all kinds of ores and rocks under mid-hardness in mine, chemical industry, cement, building materials and other industrial sections.

Introduction of Double Roll Crusher

Double roll crusher is one kind of fine crusher, designed for the fine crushing process. Especially suitable for the production scene requiring uniform discharge particle size and less dust.

Double Roll Crusher (or Roller Crusher) is used for middle crushing and fine crushing of all kinds of ores and rocks under mid-hardness in mine, chemical industry, cement, building materials and other industrial sections. This crusher has simple structure and can be operated conveniently. Ideal product size depends on adjusting space between two rollers.

Double roll Crusher With Mechanical Protection Device (Spring)

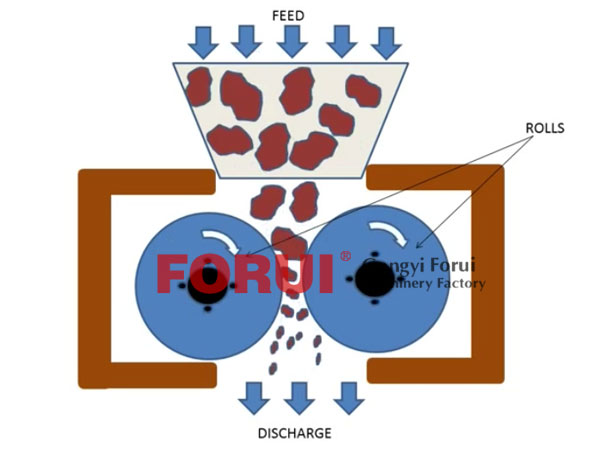

Double roll crusher works on the principle of compression force. It can easily give a reduction ratio of up to 5:1. The material to be crushed is fed between two manganese rollers (rotating in opposite directions) through a feed chute and discharged at the bottom. Out of the two rollers; one is fixed whereas the other is movable to adjust the gap setting. The roller shells are made of highly wear-resistant cast Manganese alloys and are properly machined to ensure linger bearing life and optimum operation.

Double roll Crusher with Hydraulical Protection Device(Hydraulic cylinder)

The application of Double Roll Crusher

Double roll crushers are particularly suitable for medium and fine grinding processes, demanding a strictly defined portion of fine grain and a low dust content.

Raw materials, secondary raw materials and by-products such as coke duff, coal, rock, fireclay,fertilizer, salt, glass and similar products

Roll shell of double roll crusher (High manganese steel ,wear-resistant material)

Work principle of Double Roll Crusher

The crushing rolls are driven individually and directly by means of electro-motors or with coupling and gears, counterrotating via V-belts.The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls.

The particles are drawn into the gap between the rolls by their rotating motion and a friction angle formed between the rolls and the particle, called the nip angle. The two rolls force the particle between their rotating surface into the ever smaller gap area, and it fractures from the compressive forces presented by the rotating rolls.

The features of Double Roll Crusher

- Outstanding Precision

- Sturdy Design & Construction

- Finely Machined Manganese rollers

- Easy Dismantling and assembly of parts

- Best quality spherical roller Bearing/Bush Bearings

- Accurately machined bearing housing and excellent after sales service

The shipment of Double Roll Crusher

Double roll crusher used in Rwanda for cassiterite crushing

Technical Parameter of Double Roll Crusher

| Model | Feeding size(mm) | Discarge size(mm) | Capacity(T/H) | Motor Power(kw) | Weight(T) | Dimension(mm) |

| 2PG400*250 | <35 | 0.2-8 | 2-10 | 5.5+5.5 | 1.3 | 2110*870*810 |

| 2PG400*400 | <35 | 0.2-8 | 5-12 | 7.5+7.5 | 2.3 | 2360*1100*800 |

| 2PG610*400 | <65 | 0.2-20 | 5-20 | 15+15 | 3.5 | 3510*1420*1030 |

| 2PG750*500 | <75 | 0.2-25 | 10-40 | 18.5+18.5 | 8.5 | 4210*1630*1260 |

| 2PG800*600 | <80 | 0.2-25 | 12-45 | 22+22 | 9 | 4505*1780*1320 |

| 2PG1000*700 | <100 | 0.2-30 | 20-65 | 30+30 | 12 | 5310*2175*1595 |

| 2PG1200*800 | <120 | 0.2-35 | 35-80 | 37+37 | 21 | 6290*2275*1870 |

| 2PG1500*800 | <130 | 0.2-45 | 50-120 | 55+55 | 28 | 7460*2410*2290 |