Brief Introduction of Jaw Crusher

Jaw Crusher is used to reduce the size of many different types of materials in many applications. It is applied to fine crushing of various material of which compressive strength is less than or equal to 320Mpa.

Introduction of Jaw Crusher

Jaw Crusher is used to reduce the size of many different types of materials in many applications. It is applied to fine crushing of various material of which compressive strength is less than or equal to 320Mpa, is applied to relatively small feeding material granularity and relatively small discharging gate, and is fitted for the secondary crushing.

jaw crusher is based on compound pendulum crusher. The structure is more simple and better performance. It is the earliest and most widely used all over the world. PE cruhser is widely used in mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, refractory material and ceramic etc.

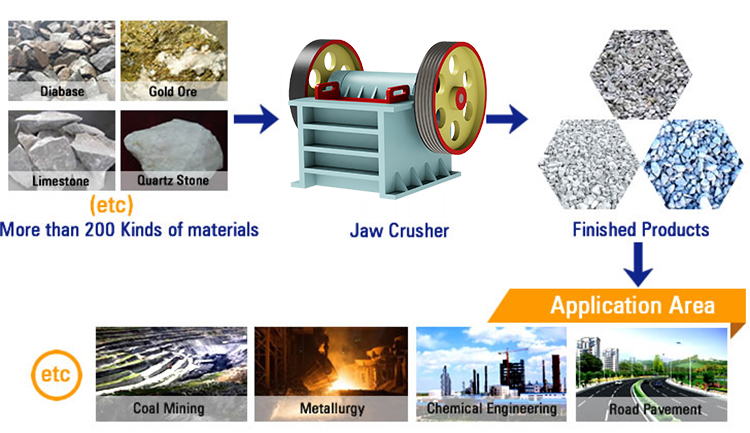

The Application of Jaw Crusher

While Jaw Crushers are mostly used as the first stage of material reduction in systems that may use several crushers to complete the circuit, the Jaw Crusher has also been used as a second-stage crushing unit. Depending on the application requirements, Jaw Crushers can be used in stationary, wheeled portable and track-mounted locations. The Jaw Crusher is well suited for a variety of applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, road and railway construction, metallurgy, water conservancy and chemical industry.

The working principle of Jaw Crusher

A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable. These two vertical manganese jaw dies create a V-shaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottom. Jaw Crushers are sized by the top opening of the crushing chamber.

The narrower bottom opening of the crushing chamber is used to size the discharge material. A toggle plate and tension rods hold the pitman tight near the bottom of the moving swing jaw. The toggle plate is designed to perform like a fuse and protect the crusher in the event that an uncrushable material enters the crushing chamber. As a rule, Jaw Crushers have a 6:1 or 8:1 ratio for crushing material.

Since the crushing of the material is not performed in one stroke of the eccentric shaft, massive weighted flywheels are attached to the eccentric shaft and powered by a motor. The flywheels transfer the inertia required to crush the material until it passes the discharge opening.

The shipment of Jaw Crusher

How to choose the right model of jaw crusher

Maximum material lump, or largest size expected to be crushed

- Tons per hour rate needing to be crushed

- Desired size of discharge material needed

- Operating hours per day.

Technical Parameter of Jaw Crusher

| Model | Feeding port size (mm) |

Maximum Feeding size |

Ouput size (mm) |

Processing capacity (t/h) |

Revolving Speed (r/min) |

Power (kw) |

Weight (t) |

Dimension (L×W×H) (mm) |

| PE-150×250 | 150×250 | 125 | 10-40 | 1-3 | 250 | 4P 5.5 | 0.8 | 720×660×850 |

| PE-200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 1.2 | 910×750×990 |

| PE-250×400 | 250×400 | 210 | 20-60 | 5-21 | 300 | 6P 15 | 2.8 | 1300×1090×1270 |

| PE-400×600 | 400×600 | 340 | 40-100 | 16-64 | 275 | 6P 30 | 7 | 1730×1730×1630 |

| PE-500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 6P 55 | 12 | 1980×2080×1870 |

| PE-600×900 | 600×900 | 500 | 65-160 | 50-160 | 250 | 6P 55 | 17 | 2190×2206×2300 |

| PE-750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 8P 110 | 29 | 2660×2430×2800 |

| PE-900×1200 | 900×1200 | 750 | 95-165 | 220-380 | 200 | 8P 110 | 52 | 3380×2870×3330 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 3.8 | 1200×1530×1060 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 13-35 | 330 | 6P 22 | 5.5 | 1380×1750×1540 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 7 | 1560×1950×1390 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 9.7 | 2140×1660×1500 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 15.6 | 2720×1950×1600 |