The lead ore can be upgraded by different methods and lead beneficiation equipments according to different types of ores, but generally speaking, lead gravity separation, lead floatation separation, or combination of gravity separation and floatation separation can be involved in the lead processing line to get high grade lead concentrate.

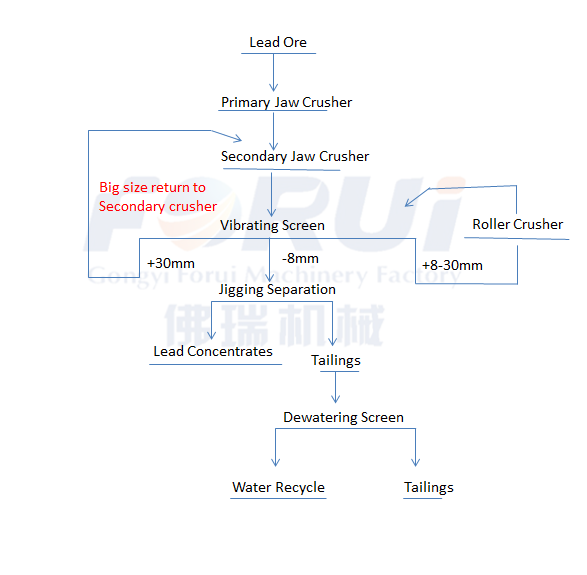

1. Lead ore gravity separation beneficiaiton process and Lead ore gravity separation beneficiation plant

Gravity separation works to separate the lead ore on basic of different specific densities between lead concentrate and the gangue. Here the specific gravity of lead(galena) is 11.34 while that of gangue is 2-3.3, and the big difference of specific gravity makes gravity separation a great method to get the lead concentrate with good beneficiation efficiency.

For lead ore of coarse and middle embedded size, simple crushing or rod milling can help to realize the dissociation of the lead granules from its attached gangue while lead of fine embedded size will need ball milling to liberate the lead grain from the gangue. Then the dissociated lead ore can go for lead gravity separator for further separation to get the final lead concentrate.

Lead ore gravity separation benefication process flowchart

The crushed lead ore will be conveyed to rod mill through hopper and feeder for further dissociation to break the intergrowth. Then the milled lead ore will be put into the lead jigging machine to gain final lead concentrate and tailings.

The lead gravity separation machine is usually for galena lead ore of coarse embedded size with its great beneficiation efficiency. As kind of easiest galena ore dressing solution, it is easy to operate, maintain with its smallest plant investment.

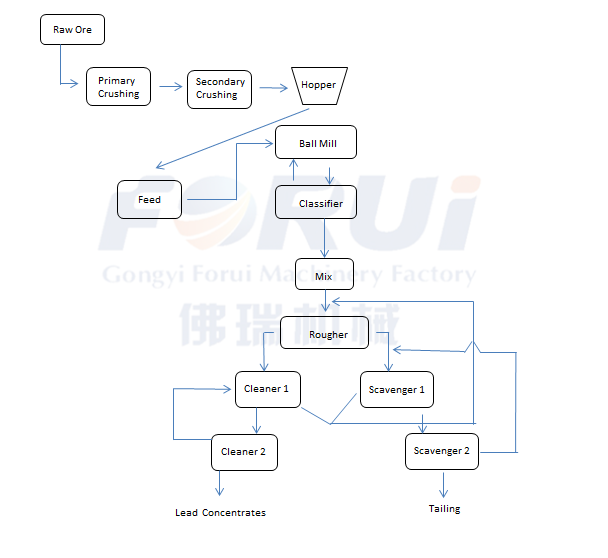

2.lead flotation separation beneficiaiton process and lead ore flotation beneficiation equipment

Lead floatation separation works of floatability difference of different materials with ite great beneficiation indication. The floatability of galena, esp. the fine inlay galena is very great, so floatation separation is the ideal beneficiation way to get lead concentrate from fine embedded lead ore.

The detailed lead floatation separation beneficiaiton process flow sheet is as below:

The crushed lead ore will be conveyed to the vibration screen to get ore of 0-5mm and +5mm. The +5mm ores will go back to the crusher fur secondary crushing. Then the ore of -5mm under screen will be put into system of ball mill and spiral classifier for milling and classifying. The ore after classification will be separated by floatation separation after agitating to get the final lead concentrate.

How to choose lead ore beneficiaiton process and lead ore beneficiation plant

Both gravity separation and floatation separation works for galena ore upgrading. But which kind of method is better for different lead mines, please?

For micro fine embedded galena, floatation separation can be used to enrich the lead ore while for coarse and fine inlay lead ore, gravity separation can be great to get qualified galena concentrate with its high recovery and good efficiency. Of course, floatation separation can also work well when it comes to coarse granule inlay lead ore, but comparing with gravity separation, the floatation needs more plant investment and operation cost.

Actually, for coarse embedded lead ore, direct jigging gravity separation after crushing can help to gain ideal concentration efficiency. The specific gravity difference between the galena grains and gangue is big and gravity separation is enough to extract the galena crystals. For some galena mine with clear inlay big size, the recovery rate, beneficiation efficiency of gravity separation is much better than that of floatation separation while operation cost and plant investment of gravity separation is much lower than that of floatation separation. So gravity separation has been becoming the main beneficiation method for galena ore.

Gongyi Forui Machinery Factory is the professional manufacturer of kinds of mineral processing line for mine of manganese, iron, gold, tin, antimony, lead, copper, diamond. With rich experience of mining beneficiation and smelting slag recycling, Forui can supply free test for you if samples about 15 kgs can be available.

If any enquiry of lead ore beneficiation process, welcome to Contact Us !

also can contact us at: Email: This email address is being protected from spambots. You need JavaScript enabled to view it. mob./wechat/whatsapp: +86 18037167566