Diamond washing machine is designed to recover diamond from kimberlite deposit or alluvial deposit. Generally diamonds are mined either from the kimberlite pipes below the earth's surface, or from alluvial deposits. So there are two kinds of diamond washing process.

1.Alluvial diamond deposits washing process and washing machine

After the diamond primary deposit is formed, it is weathered and eroded by rain, and the diamond is exfoliated with the surrounding rock. As the action of flow water,the diamond was transported and sedimentation to form placer deposites.The eluvial placer deposites is formed near primary deposite;sedimentary placer deposit is formed in river bank or river mouth;beach placer deposite is formed in coast or offshore.

In alluvial mining, considerable amounts of sand must first be removed from the area. The sand and other such components are called over-burden, and large mechanical scrapers are used to move it out of the way. Underneath the overburden lies a gravel bed, and bulldozers scoop the gravel up and set it aside in piles.The piles are then taken to diamond washing plant, where the diamonds are extracted.

The diamond in eluvial placer deposite is associated with some gravle and clay.Excavator or forklift is used to dig out the ore, then feed to washing plant to remove the clay.The washed ore will be processed by jigging machine to recover diamond from gravel.

The diamond in river or beach will be extracted by dredger or gravel pump.The big gravel will be removed by vibrating screen. the under size ore will fed to jigging machine to recover the diamond from gravel.

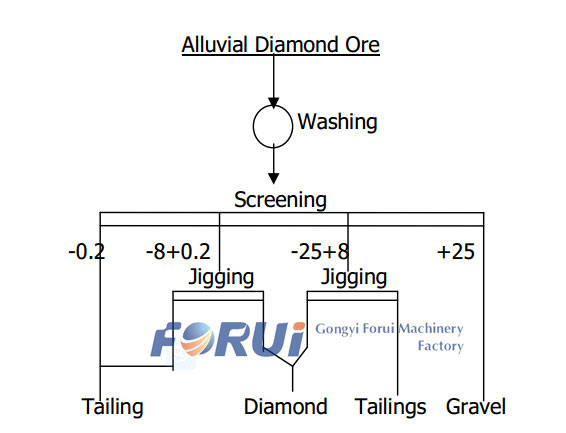

The alluvial diamond processing flowsheet as following:

2. Kimberlite washing process and kimberlite washing machine

Below-ground mining of kimberlite for diamond also requires moving enormous quantities of rock and other material in order to unearth diamond.

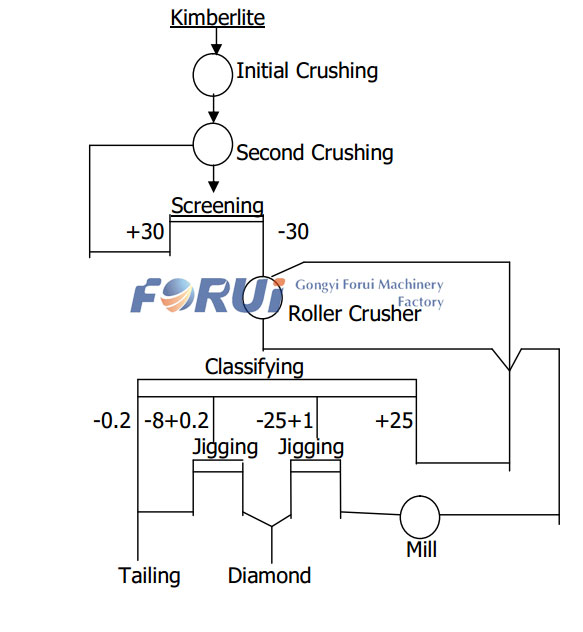

Crushing and milling is the most commonly used in excavating diamonds from kimberlite deposits. Large chunks of kimberlite are broken up into more easily transportable segments. After an initial crushing, the kimberlite passes through a grizzly, or a set of iron bars. If the crushed chunks do not pass through the grizzly, they are still too large, and they are sent back for further crushing. The crushed kimberlite is then taken for Separation processing.

3. Diamond washing machine

The jig machine is a commonly used gravity device.it works on the difference in density between gravel and diamond.As we know, the density of diamond is 3.53 g/cc, the density of associatd gravel is about 2 g/cc. there is big difference, so the jigging machine is a ideal choice for diamond recovery.

Gongyi Forui Machinery Factory is the professional manufacturer of diamond reovery plant, our diamond reocvery plants have been used in Angola,Congo,South africa. Our professional solution will be shared with your unpon receipt of your enquiry. welcome to Contact Us !

If any inquiry about the diamond recovery process, please contact us at:

Tel: +86-371-64391589 Mob& Whatsapp: +86-18037167566

Skype: ForuiMining Email: This email address is being protected from spambots. You need JavaScript enabled to view it.