Brief Introduction of Drum magnetic separator

Permanent magnet drum magnetic separator is mainly used for magnetic material separation, according to the magnetic differences between the materials and the wastes

Introduction of Drum Magnetic separator

Permanent magnet drum magnetic separator is mainly used for magnetic material separation, according to the magnetic differences between the materials and the wastes.it is mainly used for the magnetic roughing and featured separation in equipments. The magnetic system of permanent magnet drum magnetic separator consists of the strontium ferrite magnets. The Pole polarity alternated along the circumferential. Magnetic system wrap angle usually is about 106-135 ° which is related to the number of magnetic poles, polar width and pole gap width. Magnetic system drift angle usually is about 15-20° and it is adjustable.

.jpg)

application of drum magnetic separator

wet drum magnetic mineral separator is used for sorting the fine-grained strong magnetic minerals, or removing strong magnetic minerals from non-magnetic minerals. With a deep magnetic field, the machine can make a continuous row of ore feeding and discharge. It also has enough working clearance and high processing capabilities.

Wet drum magnetic separator is a developed new separating way for wet powder magnetic minerals, such as iron ore, iron sand and mill scales ect. It can be widely in metallurgical, steel works, mines and otherIndustries.

working principle of wet drum magnetic separator

The pulp flows into cell body from the pulp box, and under the water flow of the feeding spray pipe, the mineral grain will go into the feeding area of the cell body in the loose condition. In the magnetic field, the magnetic ore particles will have magnetic gathering and form magnet group or magnet chain which is influenced by the magnetic force inside the pulp and moves to the magnetic pole and finally is absorbed onto the cylinder.

Type of wet drum magnetic separator

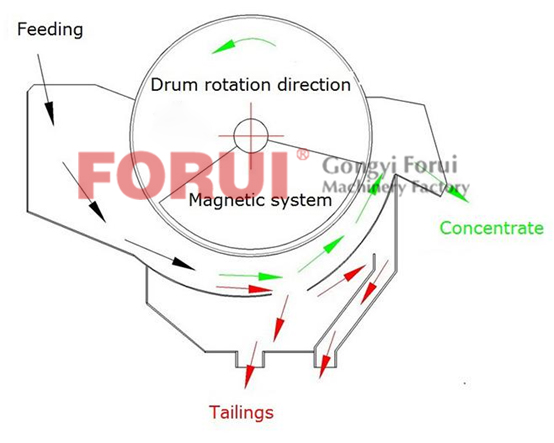

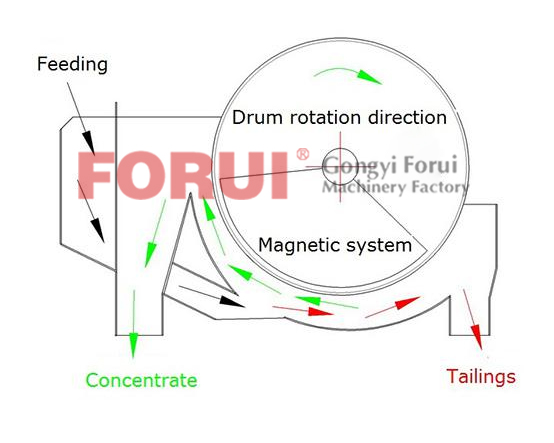

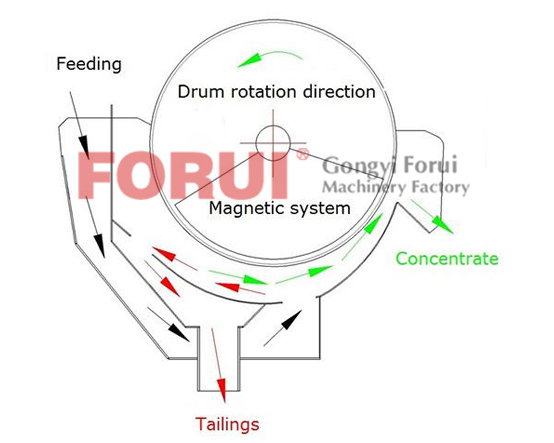

According to the different structure of the tank, the wet drum magnetic separator is divided into three kinds of concureent type, complete countercurrent type and semi counter-current type drum magnetic separator.

1.concurrent type drum magnetic separator is used to separate high magnetic minerals with size between 6 and 0 mm on the stage of roughing and cleaner process.

2. complete countercurrent drum magnetic separator is applicable to roughing and cleaning of minerals with size: 0~1.6 mm and the recovery of heavy-medium in coal preparation industry. It could discard low grade tailing in a large quantity, reduce the load of secondary grinding, improve metal recovery and save the power and washer consumption.

3.Semi-Countercurrent type drum magnetic separator is applicable to roughing and cleaning of minerals with size: 0~0.5 mm, especially suitable for the cleaning of minerals with a particle size of 0~0.15 mm. It could improve both concentrate grade and recovery rate.

Technical Parameter of Drum Magnetic separator

| Model | Drum size | Drum Surface Magnetic Intensity | Processing Capacity | Motor Power | Drum Rotating Speed | Weight | ||

| Diameter mm | Length mm | mT | t/h | m3/h | kW | r/min | kg | |

| CTB-618 | 600 | 1800 | to determine the magnetic induction intensity according to the mineral grade | 15-30 | 40-80 | 2.2 | 40 | 1340 |

| CTB-718 | 750 | 1800 | 20-45 | 60-100 | 3 | 35 | 2100 | |

| CTB-918 | 900 | 1800 | 25-40 | 70-120 | 4 | 28 | 2900 | |

| CTB-1018 | 1050 | 1800 | 45-60 | 110-160 | 5.5 | 22 | 4000 | |

| CTB-1021 | 1050 | 2100 | 50-70 | 140-200 | 5.5 | 22 | 4500 | |

| CTB-1024 | 1050 | 2400 | 60-80 | 170-260 | 5.5 | 22 | 5000 | |

| CTB-1030 | 1050 | 3000 | 80-120 | 240-380 | 7.5 | 22 | 6300 | |

| CTB-1218 | 1200 | 1800 | 60-75 | 160-260 | 11 | 17 | 5000 | |

| CTB-1224 | 1200 | 2400 | 80-110 | 240-330 | 11 | 17 | 5900 | |

| CTB-1230 | 1200 | 3000 | 100-140 | 260-460 | 11 | 17 | 7200 | |

| CTB-1236 | 1200 | 3600 | 120-160 | 300-550 | 15 | 17 | 8200 | |

| CTB-1240 | 1200 | 4000 | 130-170 | 330-600 | 15 | 17 | 10000 | |

| CTB-1245 | 1200 | 4500 | 150-200 | 380-660 | 18.5 | 17 | 12000 | |

| CTB-1530 | 1500 | 3000 | 100-180 | 290-480 | 15 | 14 | 11500 | |

| CTB-1540 | 1500 | 4000 | 150-200 | 300-540 | 22 | 14 | 14500 | |

| CTB-1545 | 1500 | 4500 | 180-240 | 400-650 | 30 | 14 | 15500 | |

| CTB-1550 | 1500 | 5000 | 210-280 | 500-750 | 30 | 14 | 17500 | |

| CTB-1824 | 1800 | 2400 | 100-140 | 260-460 | 15 | 12 | 9100 | |

| CTB-1830 | 1800 | 3000 | 140-190 | 350-560 | 18.5 | 12 | 12300 | |

| CTB-1840 | 1800 | 4000 | 200-260 | 400-650 | 30 | 12 | 18500 | |

| CTB-1850 | 1800 | 5000 | 280-320 | 550-800 | 37 | 12 | 23000 | |