Brief Introduction of Gold Centrifugal Concentrator

Gold Centrifugal Concentrator is kind centrifugal concentration equipment. It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation.

Introduction of Gold Centrifugal Concentrator

Gold Centrifugal Concentrator is kind centrifugal concentration equipment. It can be used not only for placer gold mining, but also for hard rock mining to recover the natural gold, replacing amalgamation. It is also used to recover gold from the tailings.Gold centrifugal concentrator is an important gravity beneficiation equipment developed by our factory. It is proved by experienced practices that this equipment is high efficient for recovery of placer gold, rock gold, lode gold and monomeric gold in multi-metal ore. It had earned high reputation for replacing mercury plate or any toxic chemical, removing the chemical harm to human body and conductive to environmental protecting.

Application of Gold Centrifugal Concentrator

There are many applications where Gold Centrifugal Concentrator is of particular value and cannot be equaled for economical and efficient performance. They are effective in processing precious and base metal, rare metal and non-metallic minerals. Five models are available. Application shows that the recovery can be as high as 99%, especially for the case in recovering the natural gold in lode ore with 65% of the ore having a milling size of _0.074mm, the recovery for the natural gold is expected up to 98%. For those natural gold of 0.004mm in particle size,the recovery is 97%. The cleaning up cycle is 1~4 hours, and the upgrade ratio is up to 1, 000 times.

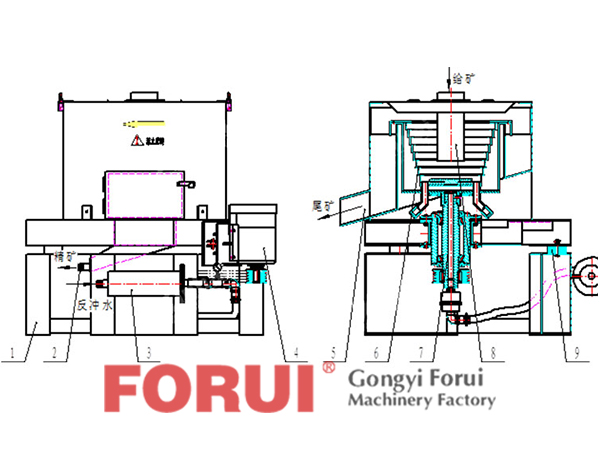

Structure of Gold Centrifugal Concentrator

The main component parts of Gold Centrifugal Concentrator is consisted with Concentrating Cone, Slurry Feeding Pipe, Secure Concentrate Plug, Tailing Discharge Pipe, Concentrate Discharge Pipe, Fluidization Water Valve and Water Inlet.

Working Principle of Gold Centrifugal Concentrator

(1)Central transmission shaft is driven by motor through belt, and then make the inner concentrate cone rotate in high speed.

(2)Fluidization water is introduced into the concentrate cone through central transmission shaft,and then spraying water to ring groove from inner cone holes, called backwash water. The water pressure level in separation process: 0.03-0.06Mpa.

(3)ineral materials enter into the inner cone groove by feeding pipe, under the high rotating configuration force, heavy ores will be deposited on the groove but the light ores will go upside along the cone liner, and finally going into tailing discharging pipe from cone upper surroundings.During the separation process, make sure the concentration discharging pipe is closed.

(4)After a cycle process, close down the machine and open the concentration pipe to collect the gold concentration.

Technical Parameter of Gold Centrifugal Concentrator

| Model | Capacity (t/hr) | Feeding Size(mm) | Feeding Density(%) | Power Requirement(kw) | Cone Rotate Speed | Water Required(t/h) | Dimension(mm) |

| STLB20 | 0.5-1.0 | 0-2.5 | 0-50 | 1.1 | 800 | 1.5-2.0 | 800*560*710 |

| STLB30 | 2.0-3.0 | 0-4 | 0-50 | 2.2 | 600 | 4.0-6.0 | 1280*1030*1135 |

| STLB60 | 8.0-12.0 | 0-6 | 0-50 | 7.5 | 460 | 10.0-15.0 | 1850*1550*1600 |

| STLB80 | 10.0-20.0 | 0-6 | 0-50 | 15 | 400 | 17.0-25.0 | 2300*1800*2200 |

| STLB100 | 50-100 | 0-6 | 0-50 | 18 | 360 | 40.0-60.0 | 2400*2400*2250 |