Brief Introduction of Circular Vibrating Screen

Circular vibrating screens, also called circular-motion vibrating screens,is new type of highly efficiency vibrating screen with multiple levels and the materials that go through the machine move in a circular motion.

Introduction of Circualr Vibrating Screen

Circular vibrating screens, also called circular-motion vibrating screens,is new type of highly efficiency vibrating screen with multiple levels and the materials that go through the machine move in a circular motion.

Circular Vibrating Screen is used to classify medium to coarse-grained bulk materials (5.0 mm to 100 mm) for screening. It is a multi-layer, high-efficiency new type of vibrating screen designed for quarry screening stone. It can also be used for coal preparation, mineral processing, building materials, electric power and chemical industry. And other departments for product grading.

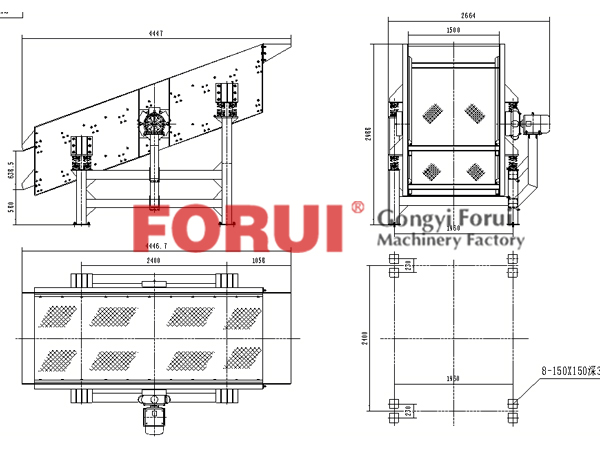

The Structure of Circular Vibrating Screen

Circular Vibrating Screen is a kind of new and highly effective vibrating screen which can be designed with multiple layers. It is composed of screen box, screen mesh cloth, suspension (or support) device, bottom frame and motor. Circular vibrating sieve is available for smelting , quarry , coal preparation, ore dressing, energy, power, chemical, construction material industries.

Feature of circular vibrating screen

- reliable structure

- strong exciting force

- high screening efficiency

- low vibration noise

- long service life

- convenient repair and safe use

work principle of Circular Vibrating Screen

Motor drives the V-belt to make the eccentric block rotate in high speed, so that producing large centrifugal force to make exciter produce the amplitude in circular motion, the materials on the screen surface will be throwing motion continuously under the function of exciter, during the process of materials contacting with the screen surface, final products will be classified.

Technical Parameter of Circular Vibrating Screen

| Model | Screen Size (㎡) | Screen Hole Size (mm) | Feeding Siz Max (mm) | Handling Capacity (T/h) | Vibration Frequency (R/min) | Power (KW) |

|

YZ918

|

1.4

|

3-30

|

100

|

3-25

|

800-970

|

5.5

|

|

2YZ924

|

1.9

|

3-30

|

100

|

4-38

|

800-970

|

5.5

|

|

YZ1020

|

2

|

3-30

|

100

|

5-37

|

900

|

5.5

|

|

YZ1230

|

3.2

|

3-50

|

200

|

7.5-78

|

800-970

|

5.5

|

|

2YZ1230

|

3.2

|

3-50

|

200

|

7.5-78

|

800-970

|

5.5

|

|

3YZ1230

|

3.6

|

3-50

|

200

|

15-86

|

940

|

7.5

|

|

3YZ1236

|

3.9

|

3-50

|

200

|

9-93

|

800-970

|

11

|

|

3YZ1542

|

5.7

|

5-50

|

400

|

50-208

|

800-970

|

15

|

|

YZ1548

|

6.4

|

5-50

|

400

|

22-162

|

800-970

|

15

|

|

YZ1848

|

8.64

|

5-100

|

400

|

22-206

|

755

|

15

|

|

2YZ1848

|

8.64

|

5-100

|

400

|

22-206

|

750

|

15

|