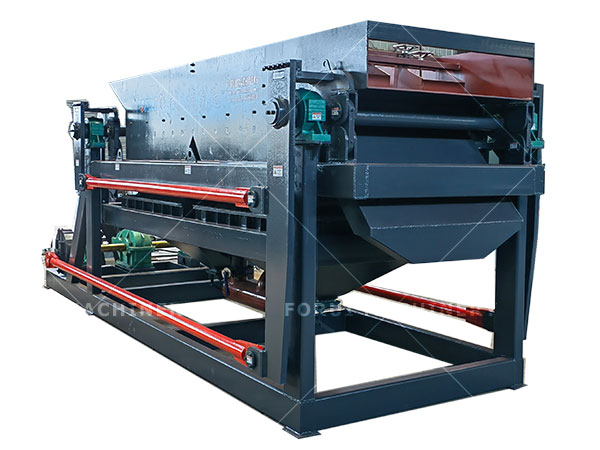

The introduction of FDX4-2 Jig machine

FDX4-2 jig machine, also called combined movable sieve jig concentrator, is one kind of new-developed gravity jig plant.It combined the acting force of pulsation water stream and movable sieve druing jigging process, featured strong water pentration force and high porosity of jig bed.The combined movbale sieve is especially suitable for the jigging separation of fluorite ore, manganese ore, iron ore and barite ore.

The structure of FDX4-2 Jig machine

The combined movable jig machine is composed of varaible speed power unit,support frame and the jigging chamber which is fixed on the support frame. The jigging chamber have three part: uppper jigging chamber , down chamber with inverted conical shap and the rubber diaphragm which connect the uper and down jigging chamber.

The jigging separation is taked placed in upper chamber, there are sieve and sieve support frame in upper jigging chamber; it also provided the material discharge port and port adjustement device at the front end part of the upper jigging chamber. The down jigging chamber also push and pull the water in jigging chamber to get pulsation water stream, there are water inlet port and water distirbution pipe in the down jigging chamber.

The working principle of FDX4-2 Jig machine

when machine is working, the motor drive eccentrical link device through reductor,make the swing arm to swing. the swing motion of swing arm causes the jigging chamber move up and down.The movement of down jigging chamber create pulsating water flow,the movement of upper jigging chamber makes the material on the sieve lift, settle and layer periodically .

The variable-speed power system drives the lever device to drive the sine wave rocker arm to make a sine wave motion. And the short connecting rod connection component drives the composite box to make a sine wave motion. At the same time, the rubber compound film of the inverting device is driven to open and close, thereby causing the medium water in the box to produce a wave of pushing and sucking.

Under the action of pulsating water flow and force of movable sieve, the feeding material move on their density, the big density material move to bottom layer, the light material move to upper layer, form differecnt layer,discharge the material separately, then the jigging separation is complete.

The technical Parameter of FDX4-2 jig machine

| Model |

feeding size (mm) |

jigging Chamber |

jingging area (㎡) |

Stroke (mm) |

stroke times (r/min) |

processing capcity (TPH) |

power (kw) |

| FDX4-2 | 1-50 | 2 | 4 | 0-150 | 0-160 | 50-60 | 18.5 |